Predictive Maintenance

Monitor and analyze critical rotating equipment, such as motors,

gearboxes, blowers, and pumps, to reduce downtime, maintenance

costs, and production

losses.

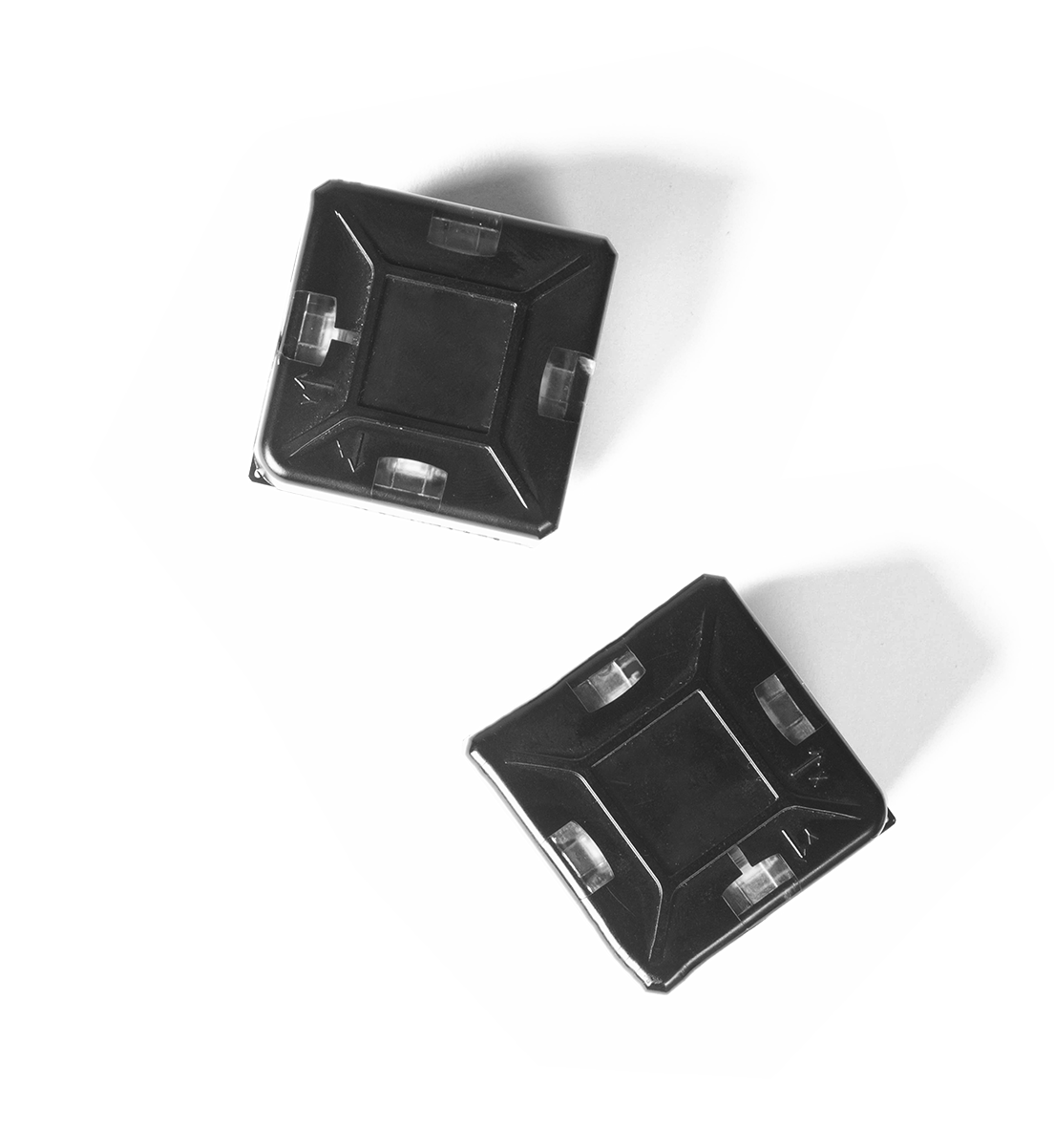

Our system collects real-time data on 3

-axis vibration velocity, acceleration, FFT

spectrum,

wave form, temperature, and

noise, running smart algorithms to detect early signs like structural

looseness, misalignment, bearing defects, imbalance, soft tooth, and

other types of

failure.

.svg)